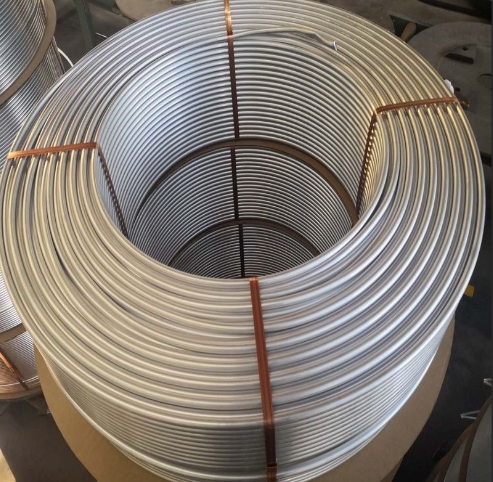

Discounted Pure Calcium Cored Wire (also known as alloy cored wire) is used to melt high-quality steel. The core of this wire is a mixture made up of metal calcium powder and iron powder. This is wrapped with a cold rolled low carbon steel strip. This type of cored wire is widely used in the iron and steel industry due to its excellent metallurgical performance. It can greatly improve molten-steel quality and help remove impurities. Therefore, it is an essential method for purifying molten-steel.

The alloyed calcium-cored wire has an excellent deoxidizer effect, and can effectively disperse all the alloying components in the liquid iron. It can also change the shape and nature of inclusions, and improve the quality of molten iron and steel. It can also reduce secondary oxidation, and improve the purity of molten iron and steel. The alloyed cored wire in the steelmaking industry is a very important invention.

Different technologies have been used in the development of cored wires. Some use sheaths that are folded, while others use welding. Sheathed cored-wires are hermetically seal, allowing them be injected deep in the ladle. The welded sheath prevents the wire from opening in the molten steel before reaching sufficient depth to generate ferrostatic pressure and keep the Ca-alloy in a liquid form. This significantly improves the metallurgical performance of cored wires compared to conventional Ca-alloy rods with a sheath made of Calcium powder.

A cored wire can also achieve a higher travel speed. The arc resistance is lower, which means that you can weld at faster rates and get the job done in less time. A cored wire that travels faster results in less slag, and therefore better quality.

Always choose the right filler metal when using a cored cable. The wrong filler metal can lead to poor welds, and increased maintenance costs. Idealy, you should only use filler metals with cored wires that have been heated to high hardness and stabilty standards.

When it comes to cored-wire applications, having the right tools and gear will make a big difference. Choosing the right spools will allow you to increase your productivity and maximize the performance of your cored wires. In addition, you should look for cored wires with a high deposition rate and deposition efficiency. These factors will result in fewer quality issues, less slag, as well as lower operating costs.

Write a Message