Electrically calcined anthracite is a type of coal that has undergone additional processing to ensure it has low levels of moisture and impurities. It's used to make metals such as aluminum, graphite, titanium dioxide and graphite oxide electrodes. Other applications are available in the manufacturing sector.

The global electrically calcined anthracite (ECA) market is expected to grow at a significant rate in the next few years. This is due both to the increased demand for steel, other metals, and electric vehicles in the manufacturing sector. ECA, an essential raw materials for these industries, provides many benefits for its users. These include cost savings, improved quality of products, and environmental benefits.

Calcining involves heating anthracite at high temperatures in order to remove volatile substances and improve the carbonization properties. It can be used for a variety of industrial processes including the production of cathode and carbon electrodes in iron and steel production. This component is also used for the production of graphite electrodes, which are then used in electric arc smelters to produce aluminum.

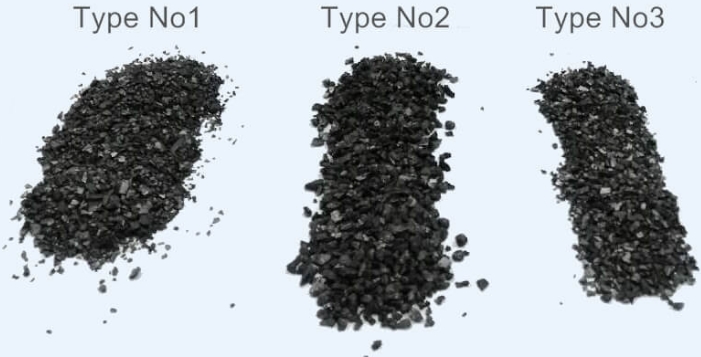

Anthracite is mined underground and then processed in a number of ways before it can either be used or sold. The first step is to break down the large anthracite chunks into smaller ones using toothed rolling. They are then divided into different sizes with sieves that have different holes. To match coals to machines, they are sized. The coal is then wrapped or bagged to be transported and sold.

The world is urbanizing and developing, and the demand for metals such as steel will increase. The market for calcined alumina is expected grow to more than 232,000,000 tonnes by the year 2021. Russia and Australia produce the most anthracite. The Russian market is the largest producer of calcined alumina in the world, with major exports to China, Japan and Germany.

The Covid-19 pandemic has had mixed effects on the calcined-anthracite market. Some segments have experienced growth, while others have seen slower expansion rates. However, as economies began to recover and industrial activity resumed, the market regained momentum. Growth in the calcined-anthracite industry is driven by the increasing demand for steel, aluminium and electric vehicles. Companies in the anthracite-smelting industry invest heavily in expanding their capacity and developing new product lines. They are also focusing on improving their marketing and distribution networks to increase their share of the market. Persistence Market Research’s report on the global Calcined Anthracite Market provides an in-depth and unbiased analysis of this market. It includes historical data from 2018 through 2022, as well as forecasts for 2023-2033. The report also highlights important trends and opportunities that market players can take advantage of. The research study is segmented by region, providing an in-depth analysis of the North America, Europe, Asia Pacific, and RoW markets.

Write a Message