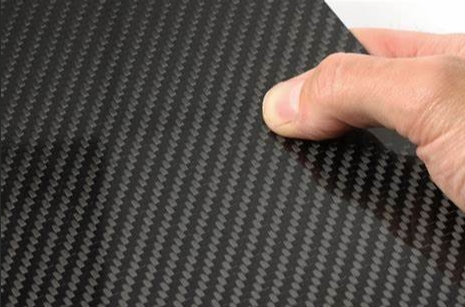

Carbon fibre is an incredibly versatile material that's known for being lightweight and strong. This material can be found everywhere from the most luxurious automobiles and sporting equipment like skis to aeronautical solutions and medical items. The market for high-performance products is growing rapidly due to its many uses.

The anthracite-carbon media used by municipal water filters is chosen because it has excellent filtering qualities and costs less than other technologies, such as reverse Osmosis. Anthracite carbon media can be used to filter water after it has gone through gravity sand filters. Its physical properties make anthracite ideal for such a treatment.

It has proven to be an effective tool in treating water. It can remove contaminants like lead, chloride, and cyanide. Activated carbon is made either physically or chemically by activating the coal. Chemical activation is achieved by using a substance like KOH to oxidize the coal. Traditionally, activated coal is produced by combining both physical and chemicals activation.

The yield of activated carbon produced by physical activation is usually lower than that achieved through chemical activation, but it's the most cost-effective method for producing this material. The density and ash content of the coal are key factors that affect the activation. Anthracite has a high density and ash level, making it difficult to physically activate. The chemical activation method can effectively activate anthracite.

To study the graphitization, the porous structure and the graphitization degree of the composites prepared from the four different materials studied (a commercially impregnating coke-tar-pitch and two thermally and foundry treated coke-tar-pitch) as well as four granular carbides. The variations in the carbon arrangement order, microcrystal size and graphitization degree were analyzed by Raman spectroscopy and X-ray diffraction. The influencing factors in the graphitization process were investigated with regard to their effects on reaction thermodynamics and kinetics.

We have observed that composites of carbon containing anthracite are more porous than their counterparts. Anthracite's distinctive textile structure may have contributed to this result. Additionally, as carbonization occurs at higher temperature, amorphous zones are gradually replaced by edges that have crystalline structure.

Anthracite samples were subjected both to physical and chemical activation by steam injection for 1 to 6 hours, at 700 degrees Celsius. The physical activation increased the micropore and the mesopore volumes, while the chemical activation decreased them. Due to the relatively low amount of amorphous matter and density, this result indicates that anthracite has a high potential for chemical activated carbon production. These results may help to improve coal reactivity and increase the efficiency of activated charcoal production.

Write a Message