In the intricate world of metallurgy, the properties of steel are not solely determined by its composition, but also by its microstructure. A crucial factor in this microstructure is the grain size, which directly influences the mechanical properties of steel. The addition of calcium during steel production has emerged as a powerful technique for refining grain structures. This article explores the significance of calcium in steel grain refinement, its underlying mechanisms, benefits, and challenges.

Grain refinement refers to the reduction in the size of individual crystalline grains in the steel's microstructure. Smaller grains mean a higher number of grain boundaries, which can hinder dislocation movement and enhance the material's strength and toughness. Grain refinement is particularly vital in applications where the steel needs to withstand significant stresses and pressures.

The Role of Calcium:

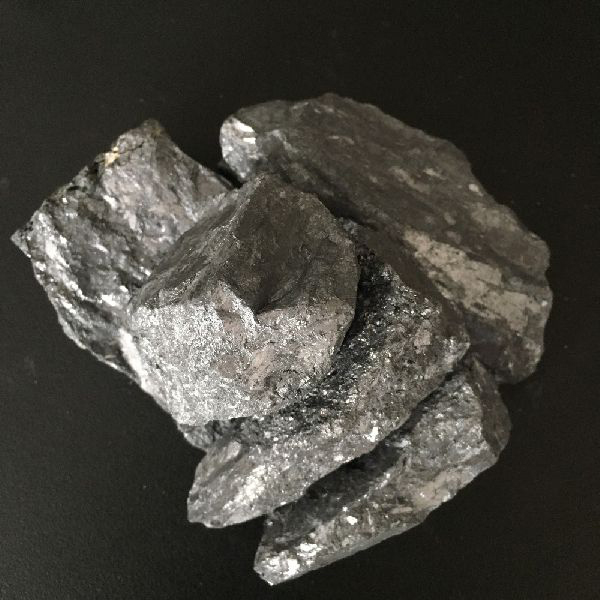

Calcium, when introduced into the steel melt, plays a multifaceted role in the grain refinement process. It influences the formation of non-metallic inclusions, the solidification process, and the subsequent grain growth. The interaction between calcium and various elements in the steel composition affects the kinetics of grain nucleation and growth, ultimately leading to a finer-grained microstructure.

During the solidification of molten steel, calcium-rich inclusions act as nucleation sites for the formation of small grains. These inclusions encourage the formation of numerous nuclei, resulting in a finer distribution of grains as the steel solidifies. This nucleation effect leads to a more refined grain structure in the final product, enhancing its mechanical properties.

Effects on Grain Growth Inhibition:

The presence of calcium in steel also inhibits the growth of grains during cooling and solidification. The pinning effect of calcium-rich inclusions on grain boundaries impedes the migration of grain boundaries, preventing the growth of large grains. This process leads to a more uniform distribution of grain sizes, resulting in improved mechanical performance across the steel material.

Inclusion control is a crucial aspect of grain refinement through calcium addition. The calcium reacts with oxygen and sulfur, forming compounds like calcium oxide (CaO) and calcium sulfide (CaS). These compounds bind with other impurities in the steel, promoting their removal as slag or floating inclusions. By controlling the types and sizes of inclusions, calcium contributes to the overall quality of the steel's microstructure.

Benefits and Challenges:

The benefits of using calcium for grain refinement are manifold. Finer grains translate to improved mechanical properties, including enhanced tensile strength, toughness, and fatigue resistance. Additionally, the refined microstructure leads to better formability and workability, making the steel more suitable for manufacturing processes. However, challenges arise in optimizing the calcium content and maintaining precise control over its addition to achieve the desired grain refinement effects.

The impact of calcium-induced grain refinement extends across diverse industries. From automotive manufacturing to construction, aerospace to energy, steel with refined grains finds applications in critical components where strength, reliability, and performance are paramount. The ability to tailor the grain structure to specific applications through controlled calcium addition opens doors to innovation and efficiency.

The utilization of calcium for steel grain refinement is a testament to the intricate art of metallurgy. By understanding the mechanisms through which calcium influences grain size, metallurgists can engineer steel with enhanced mechanical properties and improved performance across a spectrum of applications. As industries continue to push the boundaries of material science, the incorporation of calcium into steel production stands as a vital tool in crafting a new era of high-performance materials that shape our modern world.

Write a Message