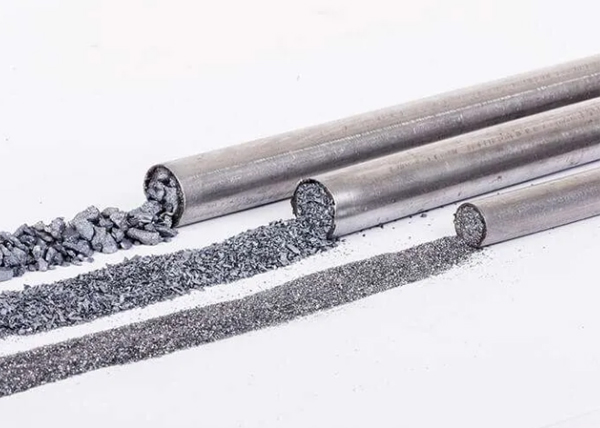

The steel smelting process is a critical step in producing high-quality steel. Calcium cored wire is widely utilized as an additive in this process to enhance steel cleanliness, modify inclusions, and improve overall performance. This article explores the benefits and applications of calcium cored wire in steel smelting, covering six key aspects: deoxidation, desulfurization, inclusion control, alloying, temperature control, and process efficiency.

Calcium cored wire is effective in deoxidizing molten steel by reacting with oxygen to form calcium oxide (CaO). Deoxidation reduces the oxygen content in the steel, enhancing its purity and reducing the risk of defects. Calcium cored wire ensures a controlled and precise addition of calcium, resulting in efficient deoxidation and improved steel quality.

Sulfur is a detrimental impurity in steel, negatively impacting its mechanical properties. Calcium cored wire aids in desulfurization by forming calcium sulfide (CaS), which binds with sulfur to remove it from the molten metal. Controlled addition of calcium cored wire facilitates efficient desulfurization, ensuring steel meets desired sulfur content requirements.

Inclusions are non-metallic particles present in steel, affecting its mechanical properties and surface quality. Calcium cored wire assists in modifying and controlling inclusions during the steel smelting process. Calcium reacts with various impurities, such as alumina and silicates, forming calcium-aluminates and calcium-silicates, which are more easily removed during refining processes. This promotes improved steel cleanliness and reduces the occurrence of defects.

Calcium cored wire can be alloyed with other elements to introduce specific properties to the steel. Alloyed calcium cored wire, such as calcium silicon cored wire, offers the advantages of both calcium and silicon. The addition of silicon improves deoxidation efficiency, enhances fluidity, and refines grain structure. This enables the production of specialized steel grades with enhanced mechanical and metallurgical properties.

Maintaining proper temperature control during the steel smelting process is crucial. Calcium cored wire aids in temperature control by releasing heat during the exothermic reaction with oxygen and other impurities. This helps to achieve and maintain the desired temperature range for efficient steel production. Effective temperature control ensures proper steel chemistry and facilitates subsequent processing steps.

Calcium cored wire contributes to process efficiency by enhancing the overall steel smelting process. Its controlled and precise addition ensures uniform distribution and utilization of calcium throughout the molten metal. This results in consistent treatment effects, reduced variability, and improved process stability. Increased process efficiency leads to higher production yield, reduced costs, and improved profitability.

The use of calcium cored wire in the steel smelting process provides numerous benefits and applications. From deoxidation and desulfurization to inclusion control, alloying, temperature control, and process efficiency, calcium cored wire plays a vital role in enhancing steel quality, performance, and production yield. Its controlled addition ensures precise treatment, leading to improved steel cleanliness, reduced impurities, and enhanced mechanical properties. By leveraging the advantages of calcium cored wire, steel manufacturers can achieve higher standards of quality, meet industry demands, and remain competitive in the global market.

Write a Message