Calcium cored wire is a widely used additive in industries such as steelmaking and foundries for enhancing metal quality and performance. However, in an ever-evolving market, it is essential to explore alternative options that can deliver similar or improved results. This article explores six alternative options to calcium cored wire, including calcium silicon cored wire, solid calcium wire, calcium aluminate, calcium silicide, calcium carbide, and calcium-bearing desulfurization agents.

Calcium silicon cored wire is a popular alternative to pure calcium cored wire. It contains a mixture of calcium and silicon, providing a balanced combination of deoxidation and desulfurization properties. The silicon content improves the efficiency of deoxidation and helps control the inclusion morphology, resulting in improved steel cleanliness. Calcium silicon cored wire is particularly beneficial for steel grades requiring higher silicon content.

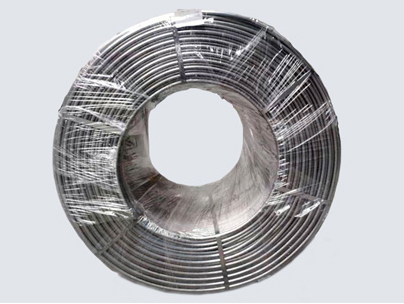

Solid calcium wire is another alternative to calcium cored wire, commonly used for desulfurization purposes. Solid calcium wire is composed entirely of calcium metal, allowing for controlled and precise addition of calcium during steelmaking processes. It effectively reacts with sulfur to form calcium sulfide, reducing the sulfur content in the metal. Solid calcium wire offers simplicity and accuracy in desulfurization, making it an attractive alternative for specific applications.

Calcium aluminate is a synthetic material composed of calcium oxide and aluminum oxide. It can be utilized as an alternative to calcium cored wire for desulfurization purposes. Calcium aluminate has a high affinity for sulfur, forming calcium sulfide. It effectively removes sulfur from molten metal, contributing to improved metal quality. Calcium aluminate is commonly used in ladle metallurgy processes, providing an efficient and economical alternative to calcium cored wire.

Calcium silicide is an alloy composed of calcium and silicon, often used as an alternative to calcium cored wire in steelmaking. It offers both deoxidation and desulfurization capabilities, similar to calcium cored wire. Calcium silicide effectively reacts with oxygen and sulfur, reducing their presence in the molten metal. Its controlled addition aids in the refinement of steel and the removal of impurities.

Calcium carbide is an alternative desulfurization agent used in place of calcium cored wire. It reacts with sulfur to form calcium sulfide, effectively reducing sulfur content in the molten metal. Calcium carbide is available in various forms, such as powder or granules, allowing for controlled addition during the steelmaking process. It provides a reliable and cost-effective alternative for desulfurization applications.

Apart from calcium cored wire, various calcium-bearing desulfurization agents are available in the market. These agents often contain a combination of calcium and other elements like magnesium or aluminum. They offer effective desulfurization capabilities and can be used as alternatives in specific applications. These desulfurization agents help achieve the desired sulfur levels in the metal and contribute to improved metal quality and performance.

As industries continue to seek efficient and cost-effective options for metal treatment, exploring alternatives to calcium cored wire becomes essential. Calcium silicon cored wire, solid calcium wire, calcium aluminate, calcium silicide, calcium carbide, and calcium-bearing desulfurization agents provide viable alternatives with various advantages and applications. Manufacturers and metallurgical professionals must evaluate their specific needs and process requirements to determine the most suitable alternative. By considering these alternatives, industries can continue to enhance metal quality, improve process efficiency, and meet the evolving demands of the market.

Write a Message