Carbon is a highly conductive material which facilitates the transfer of electrons. Its high conductivity makes carbon a good choice as an electrode in electrochemical experiments. Graphite suits these applications well because it's resistant to high temperatures and durable. Moreover, it is easy to work with and inexpensive compared to alternative materials.

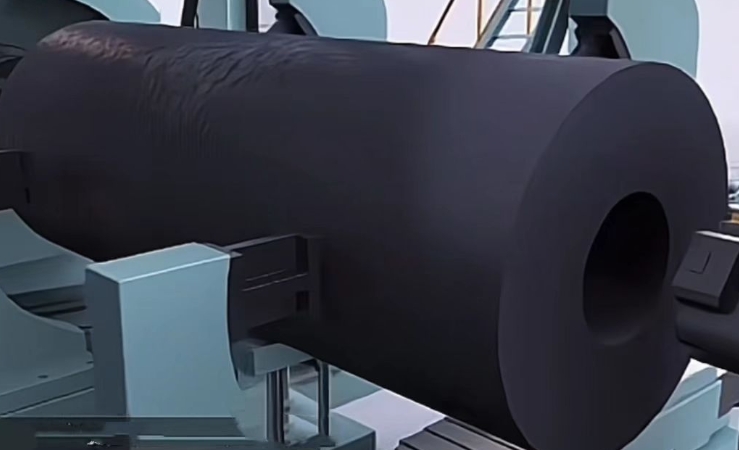

Graphite can easily be manipulated in different shapes and dimensions. It is also resistant to electrical discharge and can support a high current density. Due to its versatility, this material is widely used in industrial applications such as the smelting of non-ferrous elements like zinc or phosphorus. Also, it's widely used to make steel with an electric furnace because of its ability to withstand intense heat.

These properties also make it a great choice for use in electrical discharge machining (EDM). In this application, graphite contacts are used to shape metal parts using controlled electrical sparks. The electrodes can be shaped into very precise geometries and tight tolerances, making it a valuable tool for industrial processes with specific requirements.

EDM allows for the production of a large variety of items at a low cost. The EDM process is a reliable, accurate method that produces durable parts. Graphite works well for this method because it's able to withstand all conditions including high temperatures. Like copper electrodes of the traditional type, graphite does not get damaged by high temperatures that occur during machining.

In addition to their durability and high-temperature resistance, graphite electrodes are also highly conductive. The fact that they are highly conductive makes them a key component of the Electric Arc Furnace Steel Making Process. It ensures that scrap steel, and other material in the furnace can be melted effectively. The electrode can also be used to produce non-ferrous materials such as zinc, carbides and phosphorus.

Despite their usefulness, traditional glassy carbon electrodes (GCE) and highly ordered pyrolytic graphite electrodes (HOPG) are not ideal for many applications due to their high cost and difficult fabrication. These factors limit the amount of research that can be conducted using them.

MWI researchers created an unique fabrication procedure to create graphite-polymer electrodes that are stable and cost-effective. The characterization of these graphite-polymer composites using SEM, EDX and XPS revealed that they exhibit exceptional purity, with no metallic interferences present. Furthermore, the results of a series of dropcasted enzyme-immobilization experiments show that GDEs with 15% PE have higher faradaic EASA values than standard pencil graphite. The addition of polymer improves the performance and opens new opportunities for electrochemical research.

Write a Message