Steel industries heavily rely on graphite as the primary heat source for electric arc smelters for melting scrap metal and creating new steel. Steel demand is fueled by rapid infrastructure development in developing countries, and this will drive the industry over the forecast period.

It is important to choose the best graphite electrode for a steel mill in order to optimize performance and reduce costs. It involves carefully evaluating a mill's specific needs matched against an electrode's characteristics to ensure the best return on investment. The choice of electrode also affects the energy consumption rate, production speed, as well as quality. The highest-quality electrodes made of graphite can reduce energy costs and increase efficiency.

The Graphite-Electrode industry is currently undergoing a significant consolidation, due to the influx of Chinese investments. These companies are able to offer higher-quality electrodes for competitive prices because they have the expertise, resources and technology. This is good news for the industry because it will allow them to meet demand for high-quality products made of graphite and reduce their production costs.

To achieve this goal, producers are enhancing their production processes and implementing advanced technologies that are more environmentally friendly. This includes lowering carbon emission, increasing electrical efficiency and using alternative materials. In addition, they're integrating IoT technology and smart technologies into electrodes for monitoring real-time data. The company will be able optimize the electrodes, prolong their life and increase furnace efficiency.

A growing number of graphite-electrode manufacturers also form partnerships with other businesses to reduce their carbon footprint. The reusing of spent electrodes will reduce the amount and frequency of replacements, as well as waste and emission. The reusability and low raw material requirements of graphite electrodes also allows them to be made with less.

Majority of steel in the world is produced using blast furnaces that convert iron ore and molten metal. The resulting liquid iron is then used in an electric arc furnace to remove the impurities such as silicon, sulphur, and phosphorus. The molten steel that results is then shaped and rolled into the desired sizes and shapes.

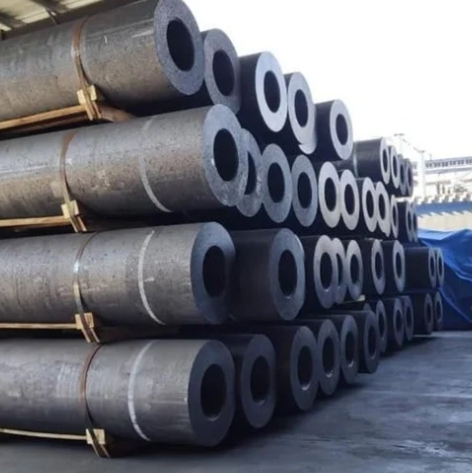

To get the best out of a furnace, it is essential to use graphite electrodes. Graphite Electrodes are made from natural flake graphite, which is extracted in large quantities around the world. Dan Carbon is currently the world’s largest producer of graphite, and it produces products for a variety industries. The company's modern manufacturing facilities use strict quality control procedures to ensure the reliability and consistency of all its products. As well, it provides customers with a wide range of services that add value to their products. These include machining and production in custom sizes. Moreover, it is committed to delivering superior customer service and quality to its global customers. It has plans to expand production in China, and other countries.

Write a Message