The introduction of cored steel wires into the process of making steel has led to a significant improvement in product quality. The cored wire used during the steelmaking is for deoxidation. Desulfurization and inclusion modification. Also, it improves yield of rare earths and metals. A cost-effective and efficient method of refining steel in molten form, it can also be used to improve the quality of a product. Also, it can be used to enhance the overall quality of steel that has been corroded.

The cored wire is an excellent flux that has an inner core made of metal calcium, and an outer coating of low carbon steel strips cold rolled. The wire is intended to be placed in the liquid steel to cause a chemical reaction. This reaction creates slag, which removes any impurities from the liquid steel and allows it to be cast more easily. The final steel product will be more durable, and the quality of the finished product is higher.

To achieve the desired results, it is necessary to operate the cored wire at the calculated speed, as this will ensure that it reaches the correct depth in the liquid steel and reacts at the optimum temperature. If you feed the cored metal wire incorrectly, it will decrease its absorption rate of calcium and affect the efficiency. Also, it is a good idea for you to collect samples of liquid stainless steel so that you can observe any possible changes to impurities as a consequence of reactions caused by a cored cable.

You should store the cored wire safely and in an area that's dry. Avoid heat and moisture, because it is prone to corrosion. Also, keep away any chemicals that may react with the silicon calcium core.

Compared to conventional cored wire, this type is much more durable and resistant to oxidation. Also, the wire is very flexible and it can resist high temperatures. It is also available in a variety of shapes and sizes to suit the requirements of different steel production processes.

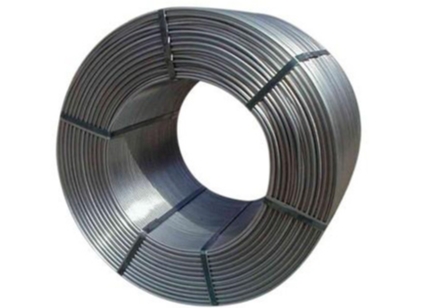

You can purchase cored steel wire in various packaging, including wood and steel pallets. Also, you can get it wrapped with PVC or stretch foil. The coil's size and form are dependent on the type of packaging, pallet dimensions, transportation method and space in steel mills for storing coils. It is also important to take into account the thickness of steel when selecting a package. Although thicker coils tend to be more expensive, they reduce the chance of damage occurring during transport and storage.

Write a Message