Calcium treatment is an important part of steelmaking. There are many advantages to this process, which include improved quality in cast iron and reduced sulfur. A very effective method to improve melting behaviour is the calcium treatment. The quality of the resulting cast product is directly related to the efficiency of the calcium treatment. Therefore, metallurgists are seeking to optimize the calcium treatment and ensure the best possible casting properties.

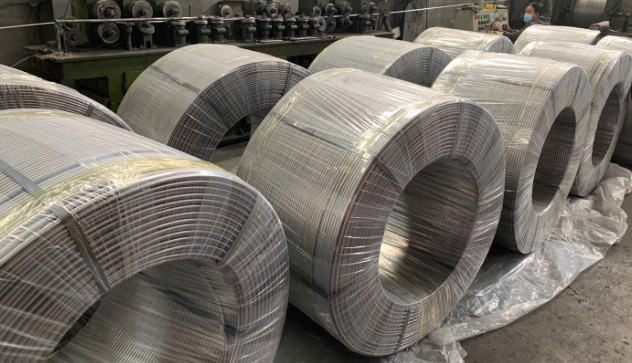

For a better calcium treatment efficiency, metalurgists examine different wire core types. Pure calcium cored cables have the most promising future. They are composed of a cored steel wire with an insert made from pure calcium. Sheaths are melted and calcium liquid is dispersed in the steel molten. The cored wires have many advantages over the traditional solid sheaths, such as less slag and carbon in steel.

The metalurgical performance for pure calcium cored cables depends on a number of factors. This includes the core and sheath temperatures as well as a properly designed process. A proper calcium atomization is required to get the optimal result. This is because the amount of alloy in the wire sheath will affect the way it atomizes. It also depends on the gradient of temperature in the core and how the metals melt.

A model for simulating the immersion of a pure calcium-cored wire into liquid steel was developed. When the results of simulations were compared to experimental data, the model was able predict the behavior of cored steel in terms melt temperature, calcium injections and slag components. The simulated and measured travel distances of the cored calcium wire are in excellent agreement.

The model's practical application in steel-making industries and casting is numerous. It is possible to determine the sheath temperature, core temperature, or both in order to maximise calcium absorption. You can use it to create a brand new calcium treatment process or evaluate an existing system. The metallurgical model can also be used to develop more accurate calibration procedures for cored wires, and to determine the effect of alloying agents on the calcium transfer process. It will also be used in the future to improve production and create more advanced wires. XLS Metals has been a manufacturer of high quality calcium cored wiring and other welding products for many years. The company conducts extensive research, improves cored wire performances and holds several production technology patents. XLS Metals is a leading global steel and casting supplier, with a commitment to quality and specialized support. For more information, please contact us.

Write a Message