There are many additives used in the metal industry. A steel-making additive, the calcium cored pure wire, is a very important one. The metal is flexible, long and cylindrical with a calcium powder filling. In a wide range of applications, it is used to treat molten stainless steel. The ladle can contain it for deoxidation and desulfurization as well as inclusion modification. It improves the quality of steel while reducing production costs. It can also be used for welding and other applications.

The use of calcium cored wire can greatly improve the quality and performance of metal products. The wire can improve surface smoothness and increase melting speeds of steel molten. The product can be used to reduce the cost and eliminate any defects. This can make it easier to produce welded tubes.

Each type of wire core has its own specific purpose. The traditional cored calcium wires can be replaced by silicon cored or aluminum wires. However, the calcium cored wire is one of the most common and has a number of benefits.

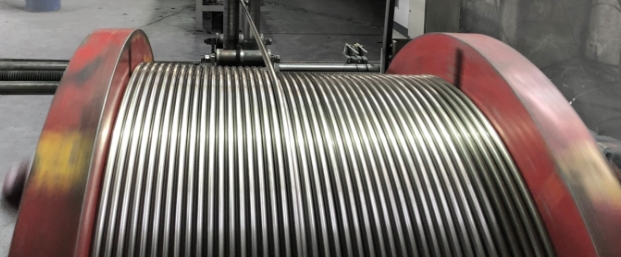

This type of cored wire has a high tensile strength and good toughness, which makes it difficult to break, so it can be used for a longer period of time without losing its shape. The diameter of the sheath is usually 9mm, and the core is made from solid metal calcium (pure calcium).

The profiling machine is used to manufacture conventionally cored cables. The half shell is then formed, the powder added and the hook closed. Wall thickness ranges from 0.4 to 6 mm. A type of cored steel wire can only be produced in certain ways, with the closure hook being about 4x thicker than its sheath. It is because of these limitations that cored-wire AM technology can only be applied to some specific materials and alloys.

The lack of uniformity in the thickness of the outer sheath and the chemical makeup of the wire core can also cause problems with the wetability of reinforcing materials with matrix materials. Agglomeration is likely to be the cause, as it can greatly reduce the effectiveness of dispersion. It can also lead to gas entrapment and stress concentration, which can reduce the performance of the composite.

For manufacturers, using cored-wires made by reliable companies and of good quality is the best way to avoid problems. This will allow them to achieve higher productivity levels, better quality products, and less time for maintenance and cleaning. To ensure they're free of defects and impurities, the cored wires must be thoroughly inspected. The cored wires should also be tightly wrapped in order to prevent any agglomeration. The manufacturing process of solid cored calcium wires will become more efficient and effective if you follow these tips.

Write a Message