It is an important corrosion resistant material used in the steel- or iron-making process. This helps to improve quality. The material is composed of different additives such as deoxidizers and desulfurizers that are then crushed into a fine powder, which can be encased within a low carbon steel strip. In the production of iron or steel, the wire core is continually fed through the feed diaphragm into the liquid ladle, causing the desired reaction.

You can use it to reduce alloy consumption and deoxidize the molten iron. The cored wire can also eliminate impurities and nonmetallic inclusions in molten steel, improving its machinability and enhancing its quality. Also, it can alter their structural properties and make them less likely to oxidize.

There are many uses for cored steel wires in the production of steel. They can be used primarily to deoxidize the metal, remove sulfur and remove inclusions. A special welding process is used to join an outer metal strip, an intermediary protective coating and a core metal of calcium. The seamless pure calcium wire has a high level of resilience, efficiency and resistance in the steelmaking processes. It also saves energy and processing costs.

Through the wire feeder, the calcium cored pure wire is easily and quickly inserted in the molten liquid steel. This wire also reduces melting loss, prevents slag from blocking the steel molten, and increases the casting efficiency. This pure calcium cored steel wire is a great tool for deoxidation, inclusion removal and desulfurization.

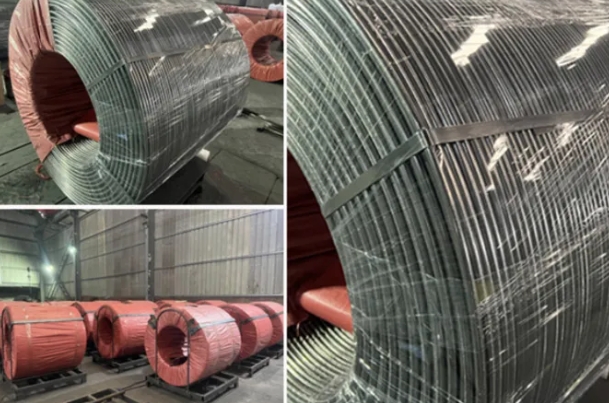

You can choose from a wide range of packaging specifications. This includes vertical and horizontal coils in steel cages or on wooden pallets. It can be customized to meet the needs of the client and shipped worldwide. Customers can get it as soon as they want. It's widely used by the steel industry.

Write a Message