Ladle metallurgy is used to refine the molten metal for specialty or high-quality applications. The steel melt is then enriched with a variety of metals and alloys. In the past, additives like these were added by mass addition. However, this was not very effective, and had a negative affect on the product's quality.

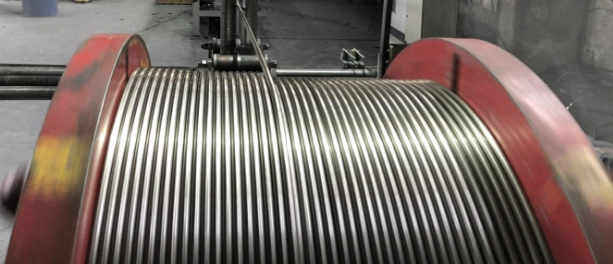

Welded cored wires can be a much more effective and economical alternative than the conventional methods for adding ingredients to the ladle. These specially-designed wires are fed into the ladle through an existing feed system. They then go directly into steel melt. This highly effective delivery method improves the metalurgical and cast quality results.

A conventional cored cable is made with a profiler and has a sheath of steel, formed to look like a shell half, that's filled with powder. It closes with a hook. Sheaths are typically about 0.4mm thick. Hi-Cal's sheath has a welded seam, which makes it hermetically seal. In this way, calcium does not escape from the sheath before reaching the correct depth within the ladle. This is necessary to create sufficient ferrostatic stress in order to keep Ca liquid. This results in a much higher efficiency of reactions between inclusions as well as superior metallurgical properties compared to other calcium iron cored copper wires.

It also eliminates any cooling of the core in the nozzle and reduces injection time by up to four times. Furthermore, it also eliminates the need for any cooling of the core in the nozzle and reduces the injection time by up to four times, which significantly improves the feed quality.

Use of solid-cored calcium lines can reduce the abrasiveness and wear of steel, as well as the nozzles and other parts of the feed system. Solid cored calcium line has a very low melting temperature and is able to handle higher temperatures than traditional pure calcium wires. It is therefore suited to a wide variety of applications, and has many advantages over similar calcium products. The use of a solid calcium cored wire in hot rolling has proven beneficial, as it improves productivity and reduces production downtime. Hi-Cal wire was successfully used at a large European plant without modifying the feeding system. It resulted to a notable increase in Calcium yield. This is due to a combination of a number of factors, including the improved sheath properties.

Write a Message