Pure Calcium Cored Wire Safety is an important issue in the steel industry. Calcium silicon wires have the potential to significantly enhance steel quality. However, they need to be handled properly in order for them be useful. The safety and instruction precautions must be followed. Failure to do so can lead to problems with the performance of the cored wire and can cause damage to equipment.

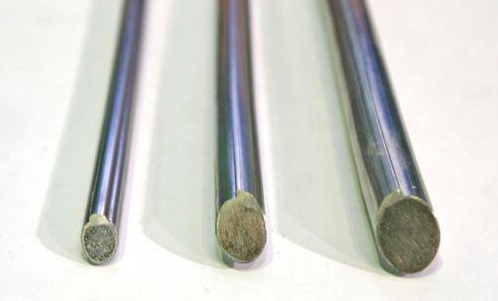

This special kind of wire is composed of three elements: an outer metal strip, a protective intermediate layer, and a core made from pure metal calcium. This wire type has several advantages over the other kinds of welding wires. It can increase the quality and durability of molten metal, as well as reduce energy usage.

Also, it has excellent desulfurization- and deoxidation-capabilities, which help to remove impurities, and thus improve the final steel product. In addition, it can help cut down on processing expenses and environmental pollution.

As a matter of tradition, wires with cores are made using a calcium powder. The metallurgical cost can be higher because of the need to consume more core than usual steel scrap. The ladle also exposes the calcium to high ferrostatic forces, which could lead to the loss of calcium metal. This can make it difficult to achieve the optimum metallurgical results.

Max-Cal (r) has developed new, high quality calcium wires that are very different from the traditional wires. It has a more dense outer sheath which allows it to be more resistant against the effects of the ferostatic pressur and release a larger amount of metallic caustic into the hot steel. It can help steel mills reduce the total cost of ownership and secure their calcium processing.

For the production of steel with high quality, cored wires have become a common option. They are an efficient way to add ferroalloys and treat liquid steel, and they can be used for a variety of applications. Also, they can reduce steel's carbon content to improve durability and strength. They can also be used in a wide range of industries, including construction and manufacturing.

If the amount is significantly exceeded, it can lead to undesirable turbulenzen during injection. This can result in undesirable turbulenzen, if this amount is greatly exceeded. These factors can also affect the quality of the steel and lead to poor welds. This can be avoided by ensuring that the slag does not get mixed in with the metal when it's injected. It's especially crucial in high-temperature situations. In these cases, the slag should be cooled and sieved before it is added to the cored wire.

Write a Message