Anthracite coal is essential for many industrial processes. The hard anthracite filler is ideal for water purification systems and has many uses, including coal-fired energy plants or the manufacture of carbon electrodes that are used to make aluminium. Anthracite's porous structure allows it to easily trap impurities from the flow of contaminated water. The result is reduced backwashing rates, lower loss of head and better treatment than single sand filter.

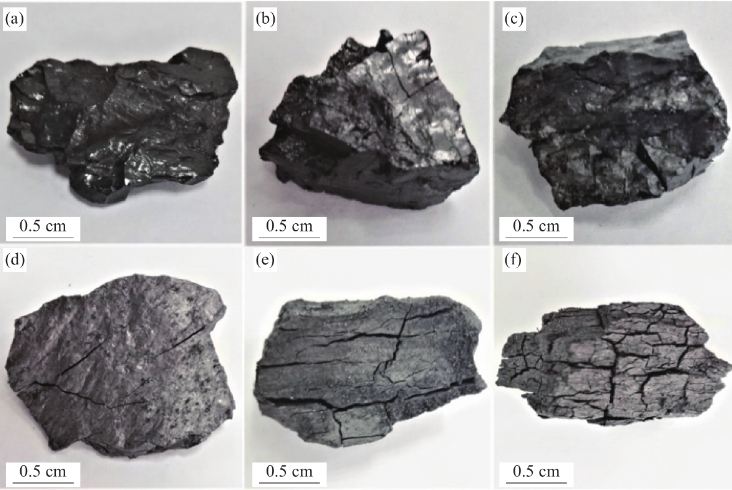

The Anthracites solid fuels are almost 100% carbon and have low levels of sulfur. Because they burn cleanly and don't leave much residue, anthracites are suitable as a domestic fuel. These coals are more durable than bituminous ones and can have metallic sheens that may be polished to decorate. These coals break down with conchoidal cracking into sharp fragments that aren't friable. They can therefore be safely used in rotary ovens and furnaces.

Its high energy and carbon content, combined with low moisture levels, make anthracite an ideal fuel for electricity generation. Because it has a lower sulphur level, the air is cleaner. Power stations, industrial furnaces, and kilns use it. Anthracite is also an excellent charge coal in metallurgy, acting at once as a carbon donor and energy provider in the iron and steel production process.

Anthracite coal is of high quality and can be easily separated from other minerals by crushing and milling. The coal is dark gray to black and dense with a semimetallic shine. Its high carbon content and low sulfur content makes it a desirable coal for metallurgy. It is used as an alternative to met coke in smelting and reducing iron ore to make steel. Natural gas can be replaced by it in power plant generators.

It is also very durable, and anthracite may be used to replace more expensive sand when building filter beds. In this way, the filtration systems can be operated with less maintenance. Its physical properties also ensure that the adsorption efficiency of the anthracite bed is maintained even as the filter system is operated with higher flow rates.

Moreover, the physical properties of anthracite allow it to be easily integrated into existing gravity sand filters. The result can be lower operating costs and higher water quality. Comparing anthracite to a single filter made of sand, municipal water plants using the material experienced less head loss, backwash, and treatment inconsistency, as well as needing less water.

As a result, anthracite filter media has become the preferred method of filtration for many municipalities. Anthracite is a great way to reduce the energy and chemicals needed for water treatment. This will have fewer environmental effects and save money over time. Anthracite's low sulphur and volatile content makes it an excellent raw material for carbon electrodes used in aluminium manufacturing, reducing greenhouse emissions.

Write a Message