The right materials are crucial when it comes to creating sustainable structures. While finding products that check all the boxes may seem impossible, advances in material science are allowing developers and construction professionals to develop materials with sustainability in mind. One such material is anthracite carbon, which offers a number of benefits to sustainable construction projects.

Anthracite coal is a form of coal that contains a high level of fixed carbon. This makes it an excellent choice for building materials with a low environmental impact. The low sulphur means that it produces very few harmful gases when it is burned. Anthracite, which is made from materials containing sulphur like bituminous oil and coal, can reduce energy costs.

As such, the anthracite material can be used to replace coal-based materials for a wide range of applications including heating and energy generation. Anthracite is also a good alternative to petroleum-based fossil fuels because it burns more efficiently and cleanly.

It can be used for industrial uses, including the production of Urea. Anthracite can be used as a resource because it is natural, and therefore safe. Anthracite can be found in calcined, anthracite. This product is widely used, from aluminum melting to steel production.

Calcined anthracite is a popular source of activated carbon, offering superior porosity and pore structure for chemical processing applications. Its unique properties make it an ideal substitute for traditional coal-based materials, as well as more expensive alternatives. Anthracite-derived activated carbons can be produced using both physical and chemical activation methods. The carbonization process is followed by a steam injection. This can be performed at different temperatures and for varying times. Chemical activation requires no carbonization before activation and KOH acts as an activating compound. It can be done for a range of KOH/anthracite (weight ratios) from 1.0 up to 4.0.

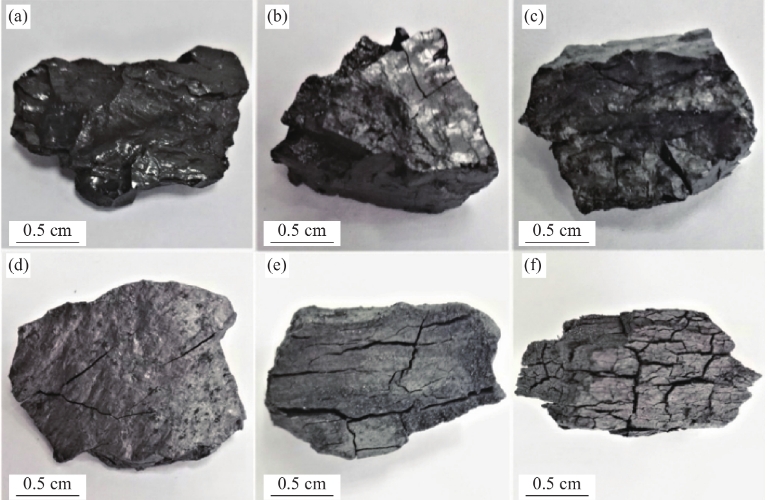

In addition to their properties, activated Carbons from anthracite exhibit a large surface area as well as high production yields. The carbon lattice of activated anthracite charcoal can be modified to alter the porousness. For instance, increasing the activation duration will result in an increase of micropores. Decreased reaction time will lead to a larger proportion of mesopores. These results suggest that anthracite derived ACC's porous properties are largely dependent on the crystalline texture and morphology. These parameters are crucial for understanding the adsorption characteristics and performance of anthracite derived ACCs.

Write a Message