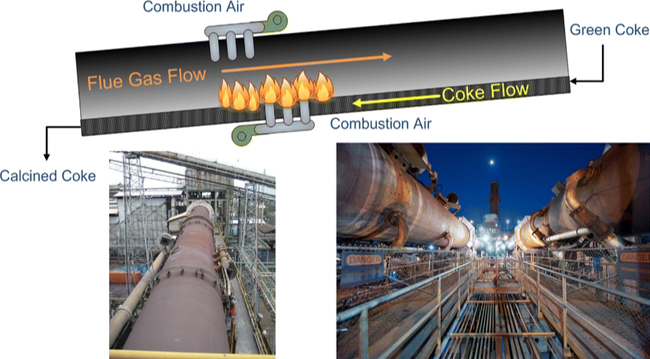

This process changes the properties of petroleum coke to make it anodized material for aluminum production. Calcination is done in a rotary oven, which heats the coke to very high temperatures. While the material is heated, it dries, devolatalises and loses moisture, leaving a more dense and crystalline structure. The calcined coke has a graphite like appearance. Rain Carbon operates seven factories in different countries. It is one the biggest producers of calcined petrol coke.

The raw material that is taken directly from the coker of a refinery is sometimes referred to "fuel grade", "anode" grade, or similar. To remove volatile materials it is necessary to perform a process called calcining. In a vertical or rotary shaft kiln the calcining takes place. The result is solid carbon with fewer impurities.

Calcined Coke has a wide range of applications in industry, from fuel to petrochemicals. The low amount of ash in the coke makes it a cleaner alternative to coal. This fuel is also high in carbon, so it's ideal for electricity production.

A calcined form of coke may also be used in place of natural gas for the production steam and hot-water for refinery processes. It helps reduce the energy cost of refineries and greenhouse gas emissions.

Unlike coal petcoke doesn't produce much sulfur dioxide. Due to its low ash level, petcoke doesn't need to undergo any prior treatment to eliminate impurities. It is because of this that calcined coal has become a popular alternative to gas.

It can be difficult to smelt. A consistent feedstock is required with the proper level of sulfur or ash. This can be difficult to achieve, and as such more smelters are blending CPC from different sources. This is because rotary kiln and shaft calciners each produce a coke with a slightly different porosity and bulk density profile.

To ensure a high quality, low sulphur product, the calcination process is closely monitored. The key parameters include temperature, residence time, and airflow, all of which are adjusted to a specific target. The resulting product is a highly electrically conductive, low sulphur coke that is ideal for the production of graphite.

The gravimetric method is used to measure the sulphur in the coke continuously during the entire calcination procedure. To determine if the coke meets the ISO 3450 standard, the results of this test are compared against a number of other standards. On the declaration and delivery form, it is recorded how much sulphur there is. Customers can then access this information.

Write a Message