Anthracite electrically calcined is a refined coal used to produce anodes in aluminum smelting. The demand for this product has been rising steadily over the years, owing to the growing demand for high-quality carbon products across several end-use industries. Furthermore, the shift towards cleaner energy sources has augmented the demand for ECA as well.

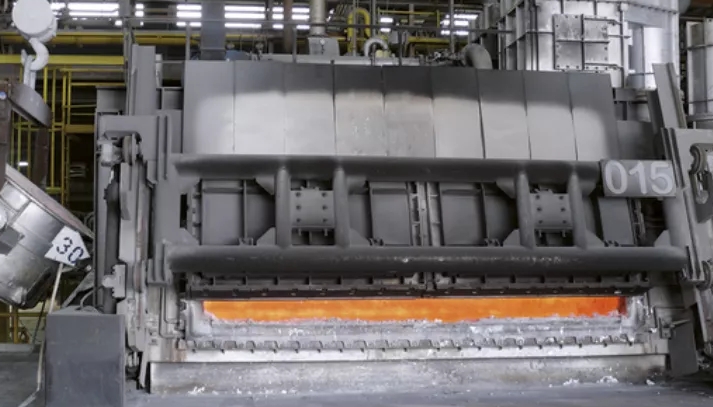

The aluminium smelting industry uses ECA to produce carbon electrodes for electric arc furnaces, which are then used in the production of aluminium. The ECA is an important raw material in the production of aluminium, so its availability is vital to the market's growth. The demand for this product is expected to rise further, owing to the rapid economic development in emerging countries.

Compared to coke, which is also used in the aluminium smelting process, ECA has lower sulfur content and higher electrical conductivity. This material has better thermal and wear resistance, is lighter to handle and easier to store. ECA, with its low sulfur and high ash content, helps reduce maintenance and operating expenses. Additionally, ECA helps maintain cathode quality during smelting.

Manufacturers of ECA are focused on increasing the production capacity and enhancing the quality of the product to meet the demands of the aluminium smelter industry. The manufacturers are investing in R&D to find new uses for the product. In addition, they are focusing on improving the supply chain management to ensure a steady availability of high-quality anthracite coal for the production of ECA.

For the best possible results, ECA producers are currently experimenting with different aggregate sizes as well as calcination times. The manufacturers are testing the effects of various variables on smelting behavior and the performance of anodes as cathodes. They can then make best use of the anthracite for aluminium melting.

Asia Pacific is the dominant region in the world for Electrically Calcined Anthracites (ECAs) because of the increased demand for Aluminium from China and India. This demand is further boosted by industrialization and urbanization in the region. In addition, the use of ECA in water filtration, petroleum refineries, paper mills, sugar refineries and cement factories is also estimated to propel the growth of the market in this region.

In the worldwide Electrically Calcined Anthracite Market, the competition is very intense. Its dynamics are greatly influenced, among other things, by market regulations and economic conditions as well as changing consumer preferences. To gain an advantage, participants in the industry should concentrate on strategic collaborations and continuous innovation of products. They should also monitor and comply with environmental regulations to maintain a sustainable business approach. In addition to investing in R&D, companies should develop innovative products with improved conductivity. The investment in R&D will enable them to increase their offering of carbon products and expand their market reach. They should also strive to match their production process with changing customer requirements to enhance the experience of customers and to strengthen brand equity.

Write a Message