Calcined Petroleum Coke (CPC) is a carbonaceous material derived from the high-temperature treatment of green petroleum coke. Its versatility, coupled with its unique properties, makes it an essential raw material in various industrial sectors. This article explores the diverse and crucial applications of calcined petroleum coke, shedding light on its significance and impact in industries worldwide.

One of the most prominent applications of calcined petroleum coke is in the aluminum industry. CPC plays a pivotal role in the production of aluminum by serving as a primary raw material for anode manufacturing. Anodes, made from CPC, are consumed in the process of electrolytic reduction, where alumina is transformed into aluminum metal. The high carbon content of CPC makes it an ideal material for anodes due to its excellent electrical conductivity and ability to withstand the harsh conditions inside aluminum smelting cells.

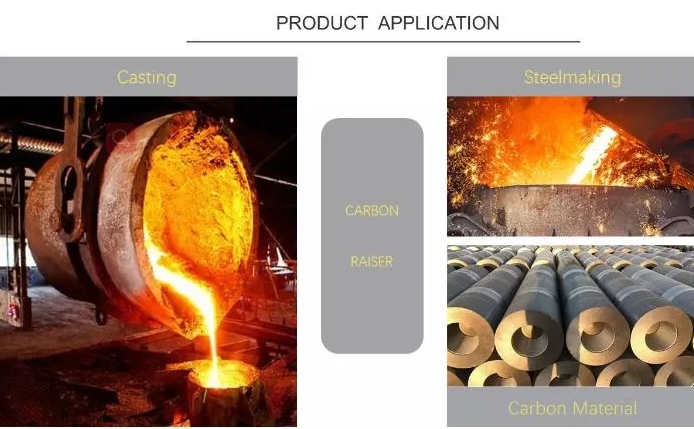

The steel industry is another major consumer of calcined petroleum coke. CPC serves as a carbon additive in the production of steel. The addition of CPC to the steelmaking process enhances the carbon content in the steel, resulting in improved mechanical properties and reducing the need for coking coal. By utilizing CPC, steel manufacturers can achieve cost-effective and environmentally friendly steel production.

Calcined petroleum coke is used in electrochemical processes, particularly in the manufacture of chlorine and sodium hydroxide by the chlor-alkali process. Carbon electrodes made from CPC are essential components in these processes. They act as conductive materials, allowing the efficient electrolysis of brine (sodium chloride solution) into chlorine gas, sodium hydroxide, and hydrogen gas. This process is vital for the production of various chemicals and plays a significant role in water treatment and the paper industry.

CPC is also utilized in the foundry industry as a carbon additive in the production of cast iron and steel. When added to the molding sand, it improves the casting process by enhancing the flowability of molten metal and reducing defects in the final product. This application ensures the production of high-quality castings for various industries, from automotive to construction.

Calcined petroleum coke serves as a precursor material for the production of synthetic graphite. Synthetic graphite has a wide range of applications, including as an anode material in lithium-ion batteries, in lubricants, and in high-temperature processes. The high-purity carbon content of CPC makes it an ideal starting point for the manufacture of high-quality synthetic graphite.

CPC is used as a fuel source in cement kilns. Its high carbon content and energy value make it an efficient alternative to traditional fuels, such as coal. Using CPC as a fuel not only reduces energy costs but also contributes to sustainable and environmentally responsible cement production.

In high-temperature chemical reactions and reduction processes, calcined petroleum coke can serve as a reducing agent and temperature moderator. Its addition can facilitate and control chemical reactions, ensuring that they occur at the desired temperature and with optimal efficiency. This is especially valuable in metallurgical processes and the production of various chemicals and alloys.

CPC is used as a carbon additive in industrial furnaces, particularly in ferroalloy production. It assists in achieving the desired carbon content and thermal properties in the furnace charge, contributing to the production of high-quality ferroalloys.

Calcined Petroleum Coke is an incredibly versatile material with a wide range of applications across multiple industries. Its unique properties, including high carbon content, excellent electrical conductivity, and thermal stability, make it indispensable in processes such as aluminum smelting, steel production, chemical electrolysis, and foundry operations. CPC also serves as a precursor for high-quality synthetic graphite and an efficient fuel source in cement kilns. Its contributions to various industrial processes highlight its importance and economic significance, underscoring the role of CPC in the advancement of industries worldwide.

Write a Message