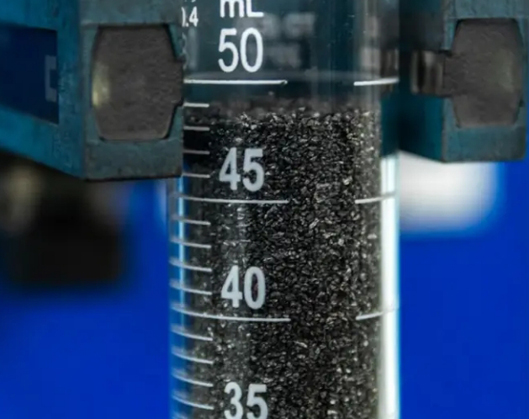

Calcined petroleum coke (CPC) is a high-purity carbon material produced by heating green petroleum coke. In the chemical industry, CPC plays a crucial role due to its versatile applications. This article elaborates on the significance and uses of calcined petroleum coke in the chemical industry.

The production of calcined petroleum coke involves two key steps: coking and calcination. Coking is a heat treatment process that converts petroleum residues into coke. After coking, the produced green coke is then calcined at high temperatures to remove moisture, volatile matter, and impurities. The final product is a high carbon content, low volatile matter, and low sulfur compound, making it an ideal raw material for numerous applications in the chemical industry.

Calcined petroleum coke is used extensively in several chemical processes. Its high heat and low ash content make it a good material for producing electrodes used in steel and aluminum industries, which are key elements in many chemical reactions. Also, its high carbon and low sulfur content make it a preferred fuel in metal and mineral melting, reducing emissions and improving processing efficiency.

While CPC is vital for various processes, it's essential to note the potential environmental impacts. The calcination process releases CO2 emissions. However, advancements in technology now allow for the capture and utilization of these emissions, turning them into beneficial by-products, thus minimizing environmental harm.

Calcined petroleum coke is a crucial component of the chemical industry, playing a pivotal role in various processes. It attributes make it ideal for electrode production, fuel for metal and mineral melting, and more, inevitably playing a significant part in the industry's sustainability. As technology progresses, we anticipate the development of more efficient and environmentally friendly uses of CPC.

Write a Message