Malleability is the ability of a metal to be deformed under stress without breaking. It is a critical property in metals because it allows them to be easily shaped and formed.

Pure calcium is not very malleable, but its malleability can be improved by alloying it with other elements. This article will explore the impact of calcium on steel ductility.

The brittleness of a material determines how easily it can be broken, disrupted, cracked, or snapped. This property is an important consideration for engineers when designing engineering products. It is also a critical factor in the safety and reliability of materials. Ductile materials can withstand a high amount of tensile stress before they fracture. Brittle materials, however, cannot deform or stretch and tend to shatter or break under low tensile stress levels.

The temperature at which a material experiences this transition is called the ductile-to-brittle transition temperature or DBTT. It depends on the material’s atomic structure and composition. For example, copper and austenitic stainless steels, which have a face-centred cubic (FCC) atomic structure, do not experience a DBTT and retain toughness for a range of temperatures.

During a brittle fracture, the atoms of a metal can no longer dislocate to plastically deform. This results in a sudden crack that consumes very little energy. Ductile materials, on the other hand, consume a large amount of energy during their failure.

When metals are subjected to tensile stress, they can either deform or rupture. A ductile metal is one that can be stretched into long, thin wires without breaking. This property is critical for safety in structural projects, like bridges. Ductile metals are also more resilient to damage and aging.

The ductility of metals depends on their structure, grain size, and crystal structure. When metals have a face-centered cubic (FCC) or body-centered cubic (BCC) crystal structure, they are more ductile than those with hexagonal close-packed (HCP) crystal structures. The ductility of metals is increased with temperature. This is because thermal energy greases the dislocations along the slip planes, allowing them to move past each other.

Various factors affect ductility, including the type of testing method used. For example, ductility in torsion tests is higher than in tensile tests. This is because tensile tests typically suffer from neck formation, which decreases ductility. Other factors that influence ductility include the length of the test specimen and the type of prestressing.

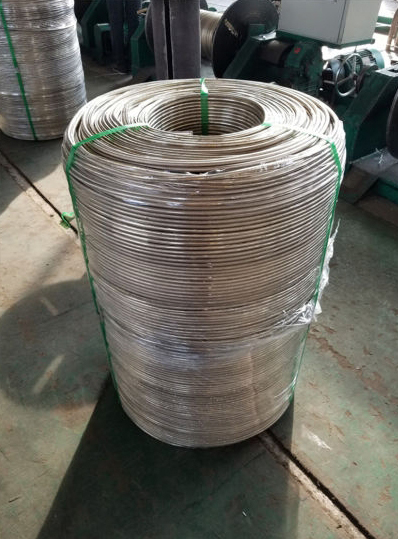

Despite being not as malleable as some metals, calcium exhibits certain unique properties that make it valuable in many applications. Among these is its ductility, which is the ability to be stretched into thin wires without breaking or cracking. This property is crucial for many industries, including electrical engineering and construction.

The ductility of calcium is primarily a result of its face-centered cubic crystal structure and low melting point. In addition, it also has a metallic bonding that allows its atoms to easily slide past each other when pressure is applied. This feature is essential for a wide range of applications, and it can be improved by alloying with other metals.

Aside from being a vital mineral in human nutrition, calcium is a useful material for manufacturing various products. Its ductility can be used to make a variety of different products, such as pipes for plumbing systems. Moreover, its malleability can be utilized to manufacture reinforcement bars, or rebars, for use in concrete structures such as buildings and bridges.

The ability of a steel to deform itself without breaking, or at least without breaking more severely than it would have under the same circumstances if not deformed is called ductility. It is very important for many metalworking applications such as welding and casting, where the metal must be shaped in an unnatural way or bent a great deal. If a material does not have enough ductility it will simply break rather than bend or flex. The ductility of steels decreases with increasing temperature, and it is important that the alloy be heated to a high enough level to retain sufficient ductility.

The ductility of a steel can be improved by adding small amounts of elements such as B and Ti, which will promote the formation of fine boron nitride precipitates at grain boundaries and modify their shape. This is particularly important because oxide inclusions evolve during cooling, and their composition can vary significantly depending on the rate at which they cool.

Write a Message