Oxygen plays a significant role in the steelmaking process, and its presence can have detrimental effects on the quality and properties of the final product. Deoxygenation is a crucial step in steel production to minimize the oxygen content and improve steel performance. Calcium Cored Wire (CCW), acting as a deoxygenating agent, has gained prominence in the steel industry. This article delves into the use of Calcium Cored Wire as a deoxygenating agent and its impact on steel production.

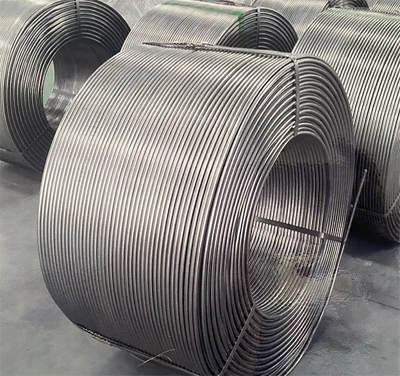

Calcium Cored Wire is a composite material comprising a steel casing filled with a powdered blend of calcium and other elements. When introduced into the molten metal during the steelmaking process, Calcium Cored Wire serves as a deoxygenating agent, facilitating the removal of excess oxygen.

Reduction of Inclusions: Deoxygenation with Calcium Cored Wire results in the removal of oxygen from the molten metal, minimizing the formation of undesirable oxide inclusions. These inclusions can have adverse effects on steel properties, such as decreased toughness, reduced fatigue resistance, and impaired weldability. By reducing oxygen content, Calcium Cored Wire improves the cleanliness and quality of the steel.

Enhanced Mechanical Properties: Excessive oxygen in steel can lead to the formation of oxide layers, which negatively impact mechanical properties, such as strength and ductility. Deoxygenation with Calcium Cored Wire helps eliminate these oxides, improving the mechanical properties of the steel and enhancing its performance in various applications.

Improved Homogeneity: Oxygen can cause uneven distribution of alloying elements and impurities in the steel matrix, leading to inconsistencies in mechanical properties. By removing oxygen, Calcium Cored Wire promotes a more homogeneous distribution of alloying elements, resulting in improved steel uniformity and predictability of performance.

Control of Steel Chemistry: Calcium Cored Wire allows for precise control over the steel's chemical composition. The addition of the wire enables the adjustment of calcium and other alloying elements, facilitating the achievement of specific steel grades and meeting customer requirements.

Cost Efficiency: Deoxygenation with Calcium Cored Wire offers cost efficiency benefits. By effectively removing oxygen, manufacturers can reduce the need for additional refining processes, such as vacuum degassing, thereby minimizing production costs while maintaining desired steel quality.

Carbon Steel Production: Deoxygenation with Calcium Cored Wire finds extensive application in the production of carbon steels. By removing excess oxygen, it improves the purity and quality of carbon steel, ensuring enhanced mechanical properties and better processability.

Alloy Steel Production: Calcium Cored Wire is also employed in the production of alloy steels. Deoxygenation helps maintain precise control over the alloying elements, enabling the production of high-quality alloy steels with specific properties, such as increased strength, improved corrosion resistance, or enhanced heat resistance.

Stainless Steel Production: In stainless steel production, deoxygenation with Calcium Cored Wire is crucial to achieve the desired steel chemistry. It helps reduce oxygen levels, minimizing the formation of chromium oxide and iron oxide inclusions, and ensuring the production of high-quality stainless steel with superior corrosion resistance.

Specialized Steel Production: Deoxygenation with Calcium Cored Wire is employed in the production of specialized steels, such as electrical steels or high-strength low-alloy (HSLA) steels. It helps refine the steel's microstructure, reduce inclusions, and enhance specific properties required for specialized applications.

Write a Message