Calcium cored wire is a crucial component in the steelmaking industry, widely used for desulfurization, deoxidation, and inclusion modification. As with any product, understanding the factors influencing its price is essential for buyers and sellers alike. In this article, we will delve into the various aspects that impact the pricing of calcium cored wire, providing insights into this important market.

Calcium cored wire is primarily composed of a steel casing filled with calcium-based powder. The price of the raw materials used in the production of calcium cored wire directly affects its overall cost. Fluctuations in the prices of steel, calcium, and other alloying elements can significantly impact the final price of the product.

The manufacturing process of calcium cored wire involves several stages, including wire drawing, powder filling, and wire sealing. Each step requires specialized equipment, labor, and energy consumption. The cost of production, including overheads, machinery maintenance, and labor wages, contributes to the final price of the product.

The interplay between market demand and supply plays a significant role in determining the price of calcium cored wire. When demand exceeds supply, prices tend to rise, while oversupply can lead to price reductions. Factors such as the growth of the steel industry, infrastructure projects, and government regulations related to emissions control influence the demand for calcium cored wire.

The quality and purity of calcium cored wire affect its performance and, subsequently, its price. Higher purity levels often command a premium due to their superior desulfurization and deoxidation capabilities. Manufacturers investing in research and development to improve the product's efficiency and quality may price their calcium cored wire higher than competitors.

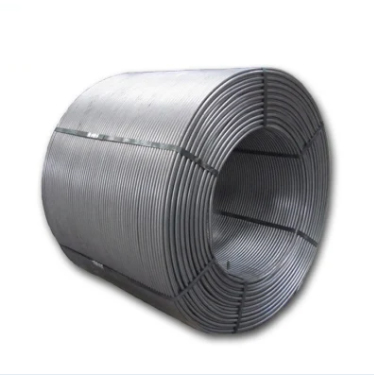

Packaging and transportation costs are significant factors in the final price of calcium cored wire. Proper packaging ensures the product's safety during transit, reducing the risk of damage. Moreover, the distance between the manufacturing facility and the buyer's location affects transportation costs, including logistics and shipping fees.

Calcium cored wire is traded globally, and fluctuations in currency exchange rates can impact its price in different regions. Changes in exchange rates between the currency of the buyer and the seller can influence the final cost of the product.

The price of calcium cored wire is influenced by various factors, including raw material costs, manufacturing process, market demand and supply, quality, packaging, transportation, and currency exchange rates. Buyers and sellers should closely monitor these factors to make informed decisions and adapt to market dynamics. Understanding the intricacies of pricing enables stakeholders to navigate the calcium cored wire market effectively, fostering a sustainable and efficient steelmaking industry.

Write a Message