In recent years, the steel industry has seen significant advancements, with the aim to improve efficiency, reduce costs, and minimize environmental impact. One such innovation is the use of cored wire in steelmaking. This article will discuss the benefits of using cored wire with good after-sale service for steelmaking and how it contributes to the overall efficiency of the process.

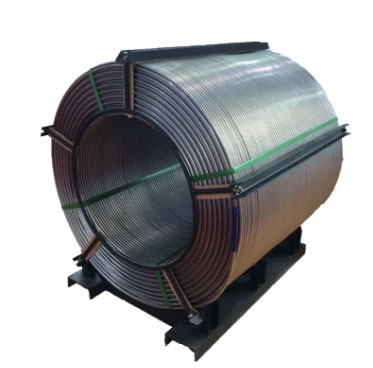

Cored wire is a tubular product filled with various additives, such as ferroalloys, metals, or chemical elements. These additives are used for refining and alloying purposes in the steelmaking process. The cored wire is injected into the molten steel or slag to introduce the necessary elements for the desired steel grade. This technology offers numerous benefits over traditional methods, such as reduced labor intensity, improved accuracy, and lower overall costs.

Enhanced Steel Quality: The precise and controlled addition of elements through cored wire technology results in a more uniform distribution of alloying elements. This leads to improved steel quality and properties, such as increased strength and ductility.

Reduced Production Costs: The use of cored wire minimizes the amount of raw materials required and reduces wastage. Additionally, it simplifies the steelmaking process, saving both time and resources.

Improved Environmental Sustainability: Cored wire technology reduces dust and fumes during the steelmaking process, contributing to a cleaner and safer working environment. It also reduces the need for additional energy sources, thereby lowering greenhouse gas emissions.

Customization: Cored wire allows for the tailor-made addition of elements according to specific requirements. This enables steel producers to create a wide range of steel grades with unique properties, catering to diverse industries and applications.

Investing in cored wire technology is only one part of the equation. To maximize the benefits of this technology, it is crucial to have access to comprehensive after-sale service. Good after-sale service ensures that customers receive:

Technical Support: A dedicated team of experts will provide guidance on the optimal use of cored wire in steelmaking, helping customers maximize efficiency and product quality.

Regular Maintenance: Regular maintenance and timely repairs are essential for the longevity and performance of cored wire injection equipment. A good after-sale service ensures that all maintenance requirements are met to keep the system functioning at its best.

Training and Education: To fully leverage the benefits of cored wire technology, it is essential that operators are well-trained and educated. Good after-sale service includes comprehensive training programs to ensure that operators are proficient in handling the equipment and injecting the cored wire effectively.

Customer-Centric Approach: A good after-sale service provider will take a customer-centric approach, understanding individual needs and providing customized solutions to address specific challenges.

Cored wire technology has revolutionized the steelmaking process, contributing to improved product quality, cost reduction, and environmental sustainability. However, to truly maximize the benefits of this technology, it is essential to invest in good after-sale service. By offering technical support, regular maintenance, operator training, and a customer-centric approach, steel producers can ensure that they continue to thrive in an increasingly competitive global market.

Write a Message