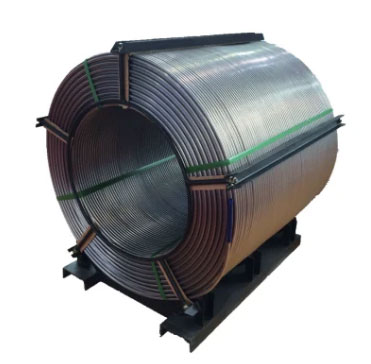

The foundry industry has long been searching for a balance between high-quality casting materials and cost-effective production. The introduction of premium quality low price cored wire for castings has proven to be a game-changer in this industry, allowing foundries to create high-quality products without sacrificing their bottom line. This innovative cored wire technology offers remarkable advantages over traditional casting materials, making it an essential component in the manufacturing process of a wide range of industries. In this article, we will explore the benefits of using premium quality low price cored wire for castings, as well as its applications and future potential.

Cost-effective production: By utilizing premium quality low price cored wire, foundries can significantly reduce the overall cost of production. The reduced material and labor costs associated with using cored wire translate into substantial savings for manufacturers, enabling them to offer competitive prices without compromising product quality.

Improved metallurgical properties: Cored wire technology enhances the metallurgical properties of the final casting products. This improvement is achieved through precise alloy additions and controlled chemical composition, resulting in increased strength, ductility, and corrosion resistance.

Reduced environmental impact: The use of cored wire for castings allows for a more efficient and environmentally friendly manufacturing process. Traditional casting methods often produce harmful emissions and waste materials. In contrast, cored wire technology minimizes waste and reduces emissions, contributing to a cleaner and greener production process.

Enhanced productivity: Cored wire technology streamlines the production process by reducing the number of steps and simplifying the overall procedure. As a result, foundries can increase their productivity, shorten lead times, and improve overall operational efficiency.

Applications of Premium Quality Low Price Cored Wire for Castings

The versatility of premium quality low price cored wire makes it suitable for a wide range of applications. Some of the most common industries that benefit from this technology include:

Automotive: High-quality, low-cost cored wire is extensively used in the production of automotive components such as engine blocks, transmission housings, and brake systems.

Aerospace: The aerospace industry relies on premium quality cored wire to manufacture critical components that require high strength, lightweight materials, and excellent corrosion resistance.

Construction: Cored wire technology is utilized in the production of construction materials such as steel reinforcement bars, concrete, and precast structures.

Oil and gas: The oil and gas industry employs cored wire technology to manufacture components that are exposed to corrosive environments, such as pipelines, valves, and drilling equipment.

The future of premium quality low price cored wire for castings is promising, as ongoing research and development continue to refine the technology and expand its applications. As industries increasingly prioritize sustainable and cost-effective production methods, the demand for cored wire is expected to grow steadily. Furthermore, advancements in material science and manufacturing technologies will likely lead to the development of new cored wire products, further enhancing the performance and efficiency of the casting process.

Premium quality low price cored wire for castings has revolutionized the foundry industry by offering a cost-effective and environmentally friendly alternative to traditional casting materials. With its numerous advantages and wide range of applications, cored wire technology is poised to become an integral part of the manufacturing process in various industries. As research and development efforts continue, the future potential of this game-changing technology is undeniable, making it a crucial asset for the foundry industry in the years to come.

Write a Message