Unlocking Foundry Potential with FeSiMg Cored Wire Technology

The foundry industry is constantly evolving, with the ongoing pursuit of innovation and efficiency driving new developments in materials and technologies. One such advancement is the use of FeSiMg cored wire in the foundry industry, which has revolutionized the production of ductile iron and enhanced overall casting quality. This article explores the benefits, applications, and working principles of FeSiMg cored wire in the foundry sector.

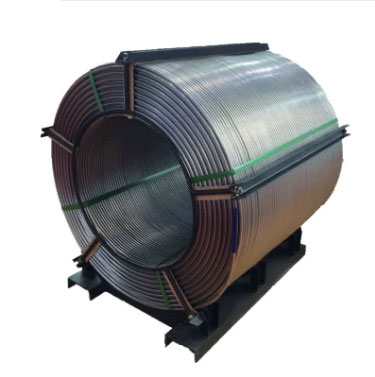

FeSiMg cored wire is a composite material consisting of a steel sheath filled with ferrosilicon magnesium (FeSiMg) alloy powder. This unique combination provides several advantages to foundries, including:

Precise Alloy Addition: The cored wire technology allows for accurate and controlled addition of the FeSiMg alloy into the melt, minimizing wastage and ensuring uniform distribution of alloying elements.

Enhanced Nodularization: The FeSiMg cored wire promotes the formation of spherical graphite in ductile iron, resulting in improved ductility, impact resistance, and fatigue strength of the cast material.

Reduced Fading: The cored wire technique minimizes the fading effect commonly associated with magnesium treatment, ensuring consistent mechanical properties and quality across multiple castings.

Increased Efficiency: The cored wire process enables faster alloy addition and reaction times, leading to reduced production downtime and increased overall foundry efficiency.

FeSiMg cored wire technology has been widely adopted in the foundry industry, particularly in the production of ductile iron castings. Some of the key applications include:

Automotive Industry: FeSiMg cored wire has played a significant role in producing high-quality castings for automotive components such as engine blocks, transmission housings, suspension parts, and brake systems.

Infrastructure and Construction: The cored wire technology is used to manufacture robust and durable cast iron components for infrastructure and construction projects, including pipes, fittings, and valves.

Heavy Machinery: The enhanced mechanical properties provided by FeSiMg cored wire make it an ideal choice for producing heavy machinery components such as gearboxes, pumps, and hydraulic systems.

The FeSiMg cored wire is fed into the molten iron using a specially designed wire injection system. As the wire is submerged into the melt, the steel sheath disintegrates, releasing the FeSiMg alloy powder. The magnesium in the alloy reacts with the sulfur and oxygen present in the melt, creating magnesium sulfide and magnesium oxide compounds, which float to the surface and are removed through slagging.

Simultaneously, the ferrosilicon component of the cored wire nucleates the graphite formation, promoting the growth of spherical graphite structures in the cast iron. This results in the desired nodularization and improved mechanical properties of the ductile iron castings.

FeSiMg cored wire technology has emerged as a game-changer in the foundry industry, offering significant benefits in terms of quality, efficiency, and precision. By enabling precise alloy addition, enhancing nodularization, reducing fading, and increasing overall efficiency, FeSiMg cored wire has proven its value in various sectors of the foundry industry. As the demand for high-quality castings continues to grow, the adoption of FeSiMg cored wire technology is expected to play an increasingly important role in the future of metal casting.

Write a Message