The electric melting process is used to purify the alumina powder into the pure white corundum we use today. Superior resistance to corrosion from acids and bases, heat, high temperatures, and consistent thermal performance. It's a little more complicated than brown corundum, but not by much. High efficiency, low heat output, and robust grinding capacity. It is ideal for precision casting & high-grade refractory materials and grinding fine grain abrasives such as high carbon steel, high-speed steel, & stainless steel.

Abrasives Made From White Fused Alumina Are Excellent For Polishing And Finishing Various Surfaces

A sandblasted surface is completely clean & white. As a preliminary polish, fine white corundum might be utilized and versatile as a product additive.

Powdered white corundum has a higher cutting power than its brown counterpart because it is more demanding and much more brittle. Excellent insulation and chemical stability. Usage Range:

It's ideal for ultrafine machining and polishing in crystal, electronics, and other industries, and it can also be utilized in producing high-end refractory materials. Fit for working with materials of high hardness & tensile strength, such as hardened steel, alloy steel, high-speed steel, high carbon steel, and many others. There are several more applications for white corundum abrasives besides sandpaper, including contact media, insulators, & precision casting sand.

During Grinding, White Fused Alumina Is Easy To Cut Into The Workpiece

The increased cost is justified by the superior self-sharpening, low calorific value, powerful grinding ability, & high efficiency of this alternative to brown corundum. For use with high hardness steels, such as high-speed steel, high-carbon steel, carbon steels, alloy steel, etc. It is excellent for use in wet sandblasting & polishing operations, ultra-fine polishing and etching in the crystal & electronics sectors, and the creation of high-tech refractories.

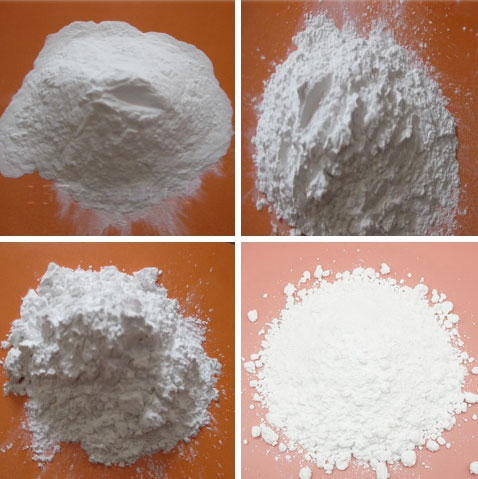

White fused alumina comprises more than 98% alumina and trace amounts of other elements, including iron oxide and silicon oxide. As a result of its high mechanical strength and resistance to heat, corundum finds applications across a variety of industries. White corundum powder is a common abrasive that finds many applications in abrasive grinding equipment. White corundum comes in a wide variety of forms, each with its unique set of applications.

Write a Message