The question of why silicon carbide has a high melting point is a common one among scientists and engineers. This hard material, which lies in between diamond and alumina on the Mohs scale, is also resistant to thermal shock. Its properties make it a useful material for electronics.

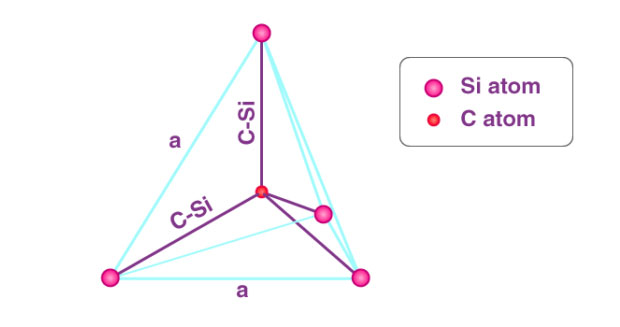

Silicon carbide is a semiconductor made of silicon and carbon. It is mass-produced as a synthetic powder since 1893. Its high melting point causes stronger electronic forces of attraction. In addition, it can form ceramics through a process called sintering. Ceramics have high endurance properties, which make them popular in many applications.

Silicon carbide is a crystalline material with a very low thermal expansion coefficient. It also has a high degree of rigidity and thermal conductivity. It can be fabricated into polycrystalline disks up to 3.5 m in diameter by chemical vapor deposition (CVD). The Herschel Space Telescope has SiC optics, and the Gaia space observatory spacecraft has a silicon carbide frame.

Silicon Carbide Nitride is a composite refractory ceramic material that is composed of 70-80% SiC and 20-30% Si3N4. This material has excellent resistance to wear and has a high melting point of 1650 degrees Celsius. It also has high thermal shock resistance and oxidation resistance. It is widely used for a variety of purposes.

Despite the vast potential for applications, silicon carbide (SiC) is a low-strength material that is prone to fracture. Its crystalline structure results in transgranular fracture and is less durable than nitride and transition metal carbides. This has led to research into how to improve toughness by modifying grain size and shape and sintering additives.

Silicon carbide has a high melting point and good corrosion resistance. It has a silica layer that develops on its surface, which plays a critical role in its corrosion resistance. Oxygen diffusion into the layer might be responsible for parabolic corrosion kinetics, but other reaction sequences may also be responsible.

Silicon carbide is a substance found in many forms. Silicon carbide, in particular, is used in the melting and heat treatment of metals. It is also used in the production of float glass, ceramics, and electronic components.

Write a Message