In this article, we will take a look at the demand and supply imbalance in the calcined petroleum coke market. We'll also look at the impact of the COVID-19 pandemic on the market, as well as the Company-wise installed capacity. Then, we'll discuss the potential of the APAC region for calcined petcoke.

The petroleum coke market is booming with the rise in the power generation and cement industries. The developing economies of Asia-Pacific are the largest consumers of petroleum coke and are leading the market in terms of demand. China and India use most of the petroleum coke in power plants to generate electricity. Europe is the second largest importer of petroleum coke due to the increasing demand for electricity in the region.

Other key growth factors for the global calcined petcoke market include population and economic development. Major manufacturers of calcined petroleum coke are enhancing production capacities to meet the rising demand. They are also establishing long-term partnerships with direct end users. These strategic tie-ups are expected to stabilize sales.

The calcined petroleum coke (CPC) market is experiencing a significant supply-demand imbalance, leading to a steep increase in prices. This is affecting the entire supply chain, including steel manufacturers and raw material suppliers. In addition, environmental regulations have forced major electrode facilities in China to shut down, reducing the availability of the product. There are several key players in the calcined petcoke market.

With the increased demand for petroleum coke, the discount between the crude oil and petroleum coke began to narrow. In addition, the Chinese government began to intervene in the market to bring down the prices of coal. As a result, the end-November price for 6.5% Sulphur Petroleum Coke was quoted at a 9.5% discount to API4 coal, down from 37% in October. However, prices rebounded in December, primarily due to increased demand for energy during the winter.

Various factors influence the calcined petroleum coke price trend, including supply and demand, and the COVID-19 pandemic is an example of such a factor. Supply and demand are the primary factors that determine the price and volume of a product or service. Understanding supply and demand can help companies identify external factors that impact prices and volumes. It is imperative for companies to understand the short and long-term supply-demand scenario for a product or service. It is also important for companies to understand the proportionality between the price and demand of a product or service.

The COVID-19 pandemic is a serious health concern and could impact the price trend of calcined petroleum coke. Several countries are concerned about the rising COVID-19 infection. As a result, a global supply disruption could negatively impact the market. Earlier, the price of PET Coke was estimated at USD 715/MT in Europe during the first quarter of 2022.

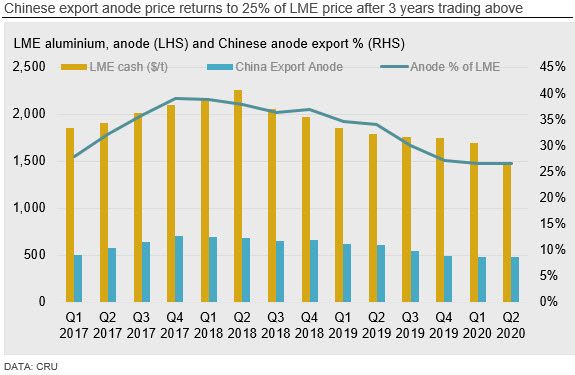

The calcined petroleum coke market is dominated by the aluminum & other metals segment, accounting for more than half of the global total. The consumption of aluminum in cement kilns and electricity generation is expected to fuel demand in the aluminum segment. China and India are the largest consumers of petroleum coke. China is also the largest producer of anode-grade coke. Sinopec, the world's largest petroleum coke producer, has an installed capacity of 22 million metric tons. It is currently operating at about 60% of its capacity.

The report also identifies the key players in the calcined petroleum coke industry. It provides a detailed analysis of the competitive landscape, flagging key players and frontline players. It also highlights the growth prospects and future scenario of the industry. It also includes an analysis of the key changed elements and offers a 10-year outlook for the industry.

There are several factors that influence the operating efficiency of a calcined petroleum coke plant. Among these factors are the average temperature and porosity. In addition, heat transfer coefficients affect the cooling rate. The more porosity present in the coke, the less effective it is in heat transfer.

Heat transfer efficiency can be analyzed by comparing the heat transfer efficiency and heat recovery efficiency of a calcined petroleum coke plant. In general, the heat transfer efficiency is increased when the porosity is 0.7 or higher. Besides, the calcined petroleum coke is more resistant to heat, which can increase its efficiency.

Write a Message