The history of cubic silicon carbide can be traced back to 1890, when an English scientist named Edward Goodrich Acheson created the first sample. He was trying to make artificial diamonds, and he heated clay, aluminum silicate, and powdered coke in an iron bowl. The mixture formed blue crystals, which Goodrich Acheson named carborundum. Another scientist, Jacques Moissan, synthesized SiC through several different routes.

Infineon Technologies AG is a leading global manufacturer of semiconductor solutions. The company employs 46,700 people worldwide. The company is expanding its product portfolio to include automotive and consumer products. It recently acquired Cypress Semiconductor Corporation and signed a supply agreement with Japanese wafer maker Showa Denko K.K.

The company is also developing cost-effective cubic silicon carbide (3C-SiC) wafers in Colorado for use in power devices. SiC is increasingly becoming the preferred material for power device development. However, traditional "4H" SiC material continues to suffer from defects, stress, and wafer diameter scaling.

SiC has been around for more than a century as an industrial material. With its unique thermal and electrical properties, the material has a wide range of applications. In recent years, its potential as a biomaterial has gained attention. In particular, it may be used in biosensors and as a biotransducer. In addition, it exhibits good tribological and electrical properties.

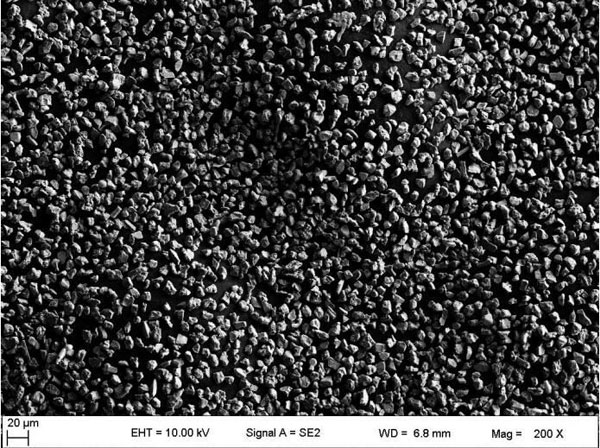

Cubic silicon carbide, also known as carborundum, is a high-performance ceramic material. It is a combination of silicon and carbon. During the production of silicon carbide, the two elements combine in a unique chemical reaction. This results in a material with exceptional abrasive properties. In addition, the material is resistant to thermal shock and chemical reactions.

The first industrial use for silicon carbide was in abrasives. It was initially discovered as a substance that would dissolve carbon in molten corundum. In 1891, a scientist named Edward Goodrich Acheson discovered the material and patented it. Acheson then used the resulting material as an abrasive and in electronic applications.

Silicon carbide is also used in the steel industry. This material is a major ingredient of crucible scrap. A high percentage of this material is used in the production of steel. It is also used as a slag additive in electric furnaces. It is more economical than ferrosilicon and carbon and produces cleaner steel. Additionally, silicon carbide is used in bulletproof vests and composite armour.

Write a Message