Silicon carbide is an important ingredient in many manufacturing processes. China, for example, produces most of the world's silicon carbide, though this product is only moderately processed. The average price of China's exports in 2016 was USD0.9/kg. Imports from China were more expensive at USD4.3/kg.

Black silicon carbide is a new generation wide band gap semiconductor material made from petroleum coke and quartz sand. It has been rising in price in recent years, reaching RMB8,000 per ton in January 2018. The price of black silicon carbide is attributed to stricter environmental protection measures, robust upstream and downstream demand, and a lack of supply. It is an extremely tough, high-purity synthetic mineral with high thermal conductivity and strength at higher temperatures. It is 7.5 times stronger than aluminum oxide and has a modulus of 410 GPa. This metal is also known to have a high dissociation temperature, dissolving at a temperature of 2600degC.

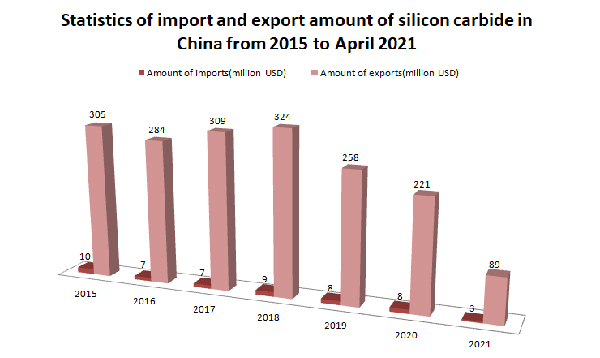

Demand for black silicon carbide has grown dramatically in China, which is the world's largest producer and exporter. Last year, China saw an increase in output of over one million tons, driven by the increasing demand from downstream sectors. While green silicon carbide was down nearly 65 percent, black silicon carbide's output increased 53.9%, according to the World Bank, while green silicon carbide saw a 68.2% decline.

The price of brown-fused alumina remains stable this month compared with the previous month. In general, white-fused alumina and corundum prices were stable. However, silicon carbide prices slightly declined. However, the demand for these materials is still high. Consequently, the cost of producing these materials is also rising.

The price of silicon carbide per ton is based on the demand of downstream markets. However, the supply is limited, which is causing a shortage in the market. Due to this, sellers in the industry are reporting longer lead times for deliveries. The supply and demand situation has also affected the price of refractory minerals. The main reason for the tight supply in the market is the disruption in China.

Silicon carbide is a material that is commonly used in the semiconductor industry. It is derived from petroleum coke and quartz sand. Its price has risen in recent years due to increasing environmental concerns and robust upstream and downstream demand. However, in recent months, green silicon carbide price per ton declined due to a slump in the market. This material is considered as one of the world's leading wide-band-gap semiconductors, and semiconductor vendors have begun launching advanced SiC-based semiconductor modules and devices since 2016.

The price of green silicon carbide per ton is increasing due to rising raw material costs, including the cost of electricity. In addition, the price of petroleum coke is rising because of the international situation. As a result, green silicon carbide grit sand enterprises have increased their product quotations. As a result, the price per ton of this material has risen to more than $2820.

SiC silicon carbide price per ton continues to be relatively high, but the current supply shortage is still a concern. Due to a shortage of brown-fused alumina and calcined alumina, the market is still tight, and many participants are reporting longer lead times. The current tightness is also one of the main factors behind the persistent price increase in refractory minerals.

The Asia-Pacific region has the largest production capacity for silicon carbide, with a variety of applications. It is used for hybrid and electric vehicles, as well as in power modules and uninterruptible power supplies. It is also used in electronics and refractories. In the future, China expects to make a significant contribution to the silicon carbide market.

Green silicon carbide prices continue to rise. The price range is $2,000 to $3300 per ton. However, this price may be higher in the short term. There are two kinds of silicon carbide: black and green. Each one has different mesh sizes, so the price differences are substantial.

Green silicon carbide is typically used for food contact applications. It can also be found in black and greenish colors. The differences in color are due to the purity of the silicon carbide. It is available in different particle sizes and is widely used in high-end cookware fluorocoatings. Manufacturers such as Micro Abrasives, Paradyne, and UK Abrasives manufacture green silicon carbide.

Write a Message