There are several cored wire injection applications. In these processes, alloy additives and flux are injected into a liquid steel bath under controlled temperature and chemical conditions. Cored wire is manufactured in advance and sized to the appropriate rate for the specific application. Then, it is inserted into the steel ladle and released at a predetermined rate. Depending on the application, the result is a steel wire with a specific chemical composition.

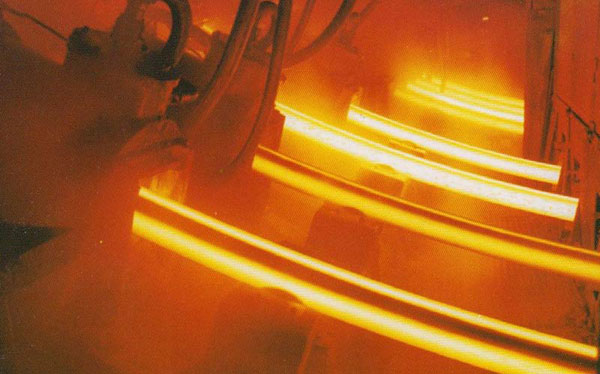

In addition to being traded on metals markets, cored wire injection is used in the steelmaking industry. They are widely used in the steelmaking process to achieve high production rates and maintain control over chemical elements in the casting process. Cored wires have many benefits, and their benefits vary depending on the application. Here are just a few examples. Cored wires have transformed the steelmaking process:

While conventional cored wires are typically produced with a sheath thickness of 0.4mm, metal-cored wires may have a sheath thickness of 0.6 to 1.5mm. Cored wires are produced using different technologies, including folded and welded sheaths. The Max-Cal(r) wire, for example, uses welding technology to provide a thin sheath. This material also produces wires with significantly better performance than other Ca-containing wires.

The overall travel distance of a wire depends on the relative importance of two competing factors. Injection speed can increase the distance, but it may also decrease the time the wire takes to melt. However, these two factors are not necessarily related to the wire travel distance. The wire travel distance is greater after a critical injection speed but decreases when it reaches the AA 'line'. While the distance increases with increasing injection rate, the position of intersection is different for different temperatures.

Write a Message